EF Model

The most respected and prevalent engine-driven cooler design in the gas compression industry is renowned for its reliability and performance. This superior design has been proven in tens of thousands of installations worldwide, demonstrating its effectiveness and durability in a wide range of demanding environments. Its widespread adoption and trust within the industry are a testament to its exceptional engineering and consistent results. Engineered to meet the rigorous standards of the gas compression industry, this cooler design ensures optimal performance, efficiency, and longevity, making it the preferred choice for industry professionals around the globe. Its proven track record in various applications highlights its versatility and adaptability, further solidifying its status as the industry standard.

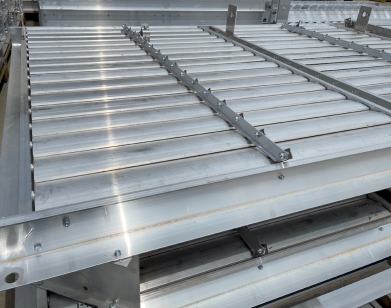

AXH air-coolers: EF Model

Advantage Summary

- Inherently more efficient Forced draft design

- Ideally suited for multiple services including engine utility cooling along with oil and multi-stages of gas compression

- High vertical discharge air velocity results in the cooler being less affected by wind direction or adjacent equipment

- Sloped sections result in greater cooling capacity in a smaller footprint or plot area

- Elimination of “top-heaviness?means greater safety, stability, and ease of handling

- Superior air-flow minimizes hot air recirculation

- Enhanced safety with excellent visual inspection and access to critical moving parts

Efficent Forced Draft Design

Sloped Sections with Superior Weight Distribution

Integral Shutters

Adjustable aluminum shutters are a standard feature on most Type EF coolers. Shutters provide superior air-flow characteristics and improved operating efficiency. Individual manual operators with remote linkage or optional air motors provide added temperature control by allowing independent louver adjustment over individual services

- Adjustable aluminum shutters, a standard feature on most Type EF coolers, provide superior air-flow characteristics and improved operating efficiency.

- Individual manual operators with remote linkage or optional air motors enhance temperature control by allowing independent louver adjustment over individual services.

Improved Safety And Maintenance

AXH Air-Coolers: EF Model

Options

- Auxiliary Louvers (located on inlet side, can provide greater control of fluid outlet temperature and can be automated)

- “Soft” quickly removable bug screens

- Discharge or personnel guards

- Access ladders

- Warm air recirculation system

vertical air cooler

The most respected and prevalent engine driven cooler design in the gas compression industry

The EF Model vertical heat exchanger is designed for applications requiring cooling and robust performance in harsh environments. This forced-draft air-cooled heat exchanger features a horizontal discharge design, making it ideal for situations where vertical space is limited. The EF Model is particularly suited for use in the oil and gas, chemical processing, and power generation industries. One of its standout features of this air-cooled heat exchanger is its high vertical discharge air velocity. It reduces the impact of wind direction or nearby equipment on performance, ensuring consistent heat dissipation. Whether you need reliable cooling in a tight space or want to minimize the impact of wind direction on your operations, the AXH EF Model heat exchanger is an ideal solution.

Discover how AXH air-coolers can enhance the efficiency and performance of your operations. Contact us today to learn more about our industry-leading cooling solutions and how we can meet your specific needs.