Air-Cooled heat exchangers

heat exchangers

AXH Air Cooler Models

At AXH air-coolers, we offer a diverse range of cooler models designed to meet the specific needs of various industries. Each model is engineered for optimal performance, durability, and efficiency. Explore our six distinct cooler models and discover the perfect solution for your cooling requirements.

Forced-draft Design

EF Model

- Forced Draft

- Vertical Fan

- Vertical Air Discharge

- Electric motor or engine drive

Advantage Summary

Inherently more efficient Forced draft design

- Inherently more efficient Forced draft design

- Ideally suited for multiple services including engine utility cooling along with oil and multi-stages of gas compression

- High vertical discharge air velocity results in the cooler being less affected by wind direction or adjacent equipment

- Sloped sections result in greater cooling capacity in a smaller footprint or plot area

- Elimination of “top-heaviness?means greater safety, stability, and ease of handling

- Superior air-flow minimizes hot air recirculation

- Enhanced safety with excellent visual inspection and access to critical moving parts

Efficent Forced Draft Design

The advantage of AXH air-coolers EF forced draft,

The advantage of AXH air-coolers EF forced draft, vertical discharge design is that fan handles cool, denser ambient air. As a result, the fan is inherently more efficient requiring less fan horsepower than induced draft coolers handling hot discharge air. Superior air flow further minimizes the recirculation of discharge hot air making it virtually unaffected by variations in wind direction or the location of adjacent equipment.

Improved Safety

A forced draft design is generally considered to be safer

A forced draft design is generally considered to be safer with the fan working against a positive static head of pressure between the fan and coils. Both fan and bearings are located in cooler ambient air and are easily visible for inspection and easy access for maintenance of all moving components.

forced draft, multiple-fan, vertical discharge design

FF Model

- Forced Draft

- Vertical Fan

- Vertical Air Discharge

- Electric motor or engine drive

Advantage Summary

Inherently more efficient Forced draft design

- Inherently more efficient Forced draft design

- Ideally suited for multiple services including engine utility cooling along with oil and multi-stages of gas compression

- Narrow width and lower profile

- Section design facilitates piping

- Single, fan shaft design

- Enhanced safety with excellent visual inspection and access to critical moving parts

Low-profile Design

The Type FF design is ideal for large HP applications where

The Type FF design is ideal for large HP applications where a single fan cooler is unable to meet the application requirements due to physical size limitations. The lower profile and narrow width can simplify shipping and reduce transportation costs due to special routing or when compared to multiple coolers. Site plan area can often be reduced in multiple unit installations.

Functional Design Cuts Piping Costs

Normal design procedures used in the rating process facilitates

Normal design procedures used in the rating process facilitates piping. This results is nozzle arrangements that reduce piping costs. The design provides for greater accessibility to piping, drive, bearings and coils. The added open, drive-end space makes engine inspection and maintenance easier which can accommodate the installation of other equipment thus maximizing use of skid space. When installed on a common single skid it can eliminate the expense of a separate “T-skid” as well as the inconvenience and costly drive and piping disassembly and field reassembly in many applications.

Induced Draft, Vertical Discharge

VI Model

- Induced Draft

- Vertical Fan

- Vertical Air Discharge

- Electric motor or engine drive

Advantage Summary

Offers combined engine, compressor, and multiple-stage

- Offers combined engine, compressor, and multiple-stage gas cooling in a single unit

- High vertical discharge air velocity results in the cooler being less affected by wind direction or adjacent equipment

- Greater accessibility to sections

- Superior air-flow control improves process operation

Vertical Discharge Design

The induce draft Type VI design offers combined engine

The induce draft Type VI design offers combined engine and compressor cooling with multiple stage gas services in a single structure. It minimizes hot air recirculation due to its vertical discharge design and is virtually unaffected by variations in wind direction or the location of adjacent equipment in applications requiring induced draft cooling.

Superior Temperature Control

Adjustable aluminum shutters are an optional feature on

Adjustable aluminum shutters are an optional feature on all Type VI coolers and are located on the air inlet side of the sections for improved control of fluid outlet temperatures. Manual or automated shutters with remote linkage provide superior air-flow control and improved operating efficiency by allowing independent louver adjustment over separate services.

most economical cooler design and a superior alternative to a “radiator”

VVI / VVF Model

- Induced / Forced Draft

- Vertical Fan

- Horizontal Air Discharge

- Electric motor or Engine Drive

Advantage Summary

Inherently more efficient Forced draft design

- Inherently more efficient Forced draft design

- Ideally suited for multiple services including engine utility cooling along with oil and multi-stages of gas compression

- Narrow width and lower profile

- Section design facilitates piping

- Single, fan shaft design

- Enhanced safety with excellent visual inspection and access to critical moving parts

Multiple services in a single unit

The Type VV is commonly used for gas, lube oil and

The Type VV is commonly used for gas, lube oil and water cooling applications where recirculation of hot discharge air is not critical. They are available in virtually all fan sizes as small as 24 inches while their flexibility allows use in a wide range of special applications

Forced or Induced Draft Design

Type VV coolers are available in either a forced (VVF)

Type VV coolers are available in either a forced (VVF) or induced draft (VVI) configuration with horizontal air flow and can be configured to meet individual installation requirements. Propeller type air-foil fans with either fixed or adjustable pitch result in higher efficiency and lower fan horsepower.

Horizontal designs provide flexibility in remote “off skid” installation

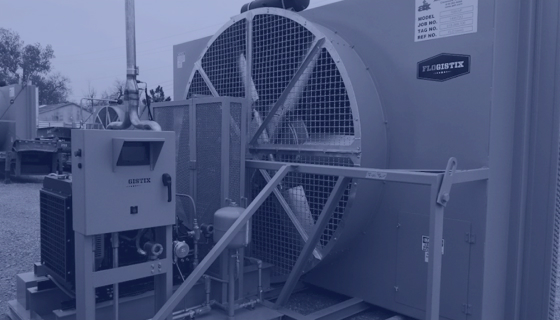

ZF / ZI Model

- Induced / Forced Draft

- Horizontal Fan

- Vertical Air Discharge

- Electric motor drive

Advantage Summary

Self-contained design eliminates field assembly and reduces

- Self-contained design eliminates field assembly and reduces transportation costs

- Ideally suited for multiple services including engine utility cooling along with oil and multi-stages of gas compression

- Forced or induced draft configurations

- Available with single or multiple fans

- Accommodates various type drive options

- Excellent access and inspection to component parts

Remote Installation

The Type ZF are commonly used for large

The Type ZF are commonly used for large hp or process applications where remote “off skid” installation is required. Structural design ensures optimum sizing of end and center panels to support all dead loads of cooler sections and piping in accordance with API and are designed to withstand 125 mph wind loading. Structural analysis for high loads available upon request. The self-contained design eliminates the need for costly field assembly and reduces transportation costs while meeting the most severe installation requirements.

Drive Options

Fans are normally driven by integrally suspended electric

Fans are normally driven by integrally suspended electric motors using HTD or V-belts but can be adapted to a variety of alternate type drives. Right ange gears in larger fan hp applications, internal, direct, engine jack shaft, or hydraulic. All drives are integrally mounted, aligned, and test run prior to shipment.

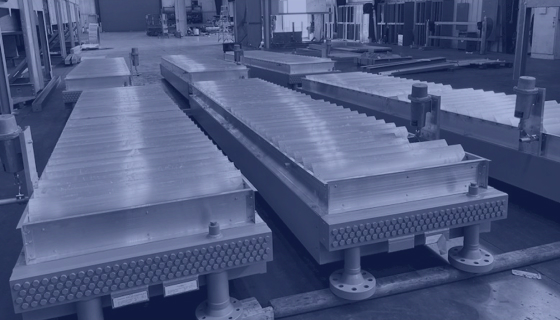

high quality finned tubes with exceptional lead times

Sections / Tube Bundles

- Section Repair

- Section Re-Tubing

- Tube Re-rolling

- Section Replacement

High efficiency fin design

The High Performance Type Fin has been proven in than 100,000

HEADERS

All code headers are constructed of SA516-70N

All code headers are constructed of SA516-70N steel utilizing a box type design and incorporating individual hex-head access plugs for easy tube maintenance or replacement in accordance with ASME code. Taper pipe plugs or shoulder access plugs which are spot faced with soft iron gaskets are standard. All tube sheets are built with single or double grooves.

Specialty Designs

AXH air-coolers also offers optional specialized

AXH air-coolers also offers optional specialized designs including a patented header as well as machined slab headers in which all long seam and a substantial amount of welding is eliminated.

We are the world’s leading manufacturer of air-cooled heat exchangers.

Discover how AXH air-coolers can enhance the efficiency and performance of your operations. Contact us today to learn more about our industry-leading cooling solutions and how we can meet your specific needs.